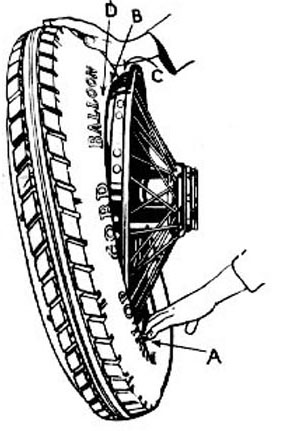

Completely deflate by removing all valve parts. At C, diametrically opposite the valve, push the edge of the type B into the well of the rim D, so as to enable the edge at A to be pulled over the edge of the rim by hand. A small spoon-like lever may be used if preferred, but force will damage the tyre and cannot assist removal because the edges are wired and inextensible.

Replace one edge first. Then insert tube, slightly inflated. Put valve stem through hole in rim and begin to replace the other edge of the cover at a point diametrically opposite the valve. When re-inflating a tyre, see that the edges of the cover are seated evenly round the rim. The edge of the tyre will pass over the edge of the rim only when it is in the position illustrated.

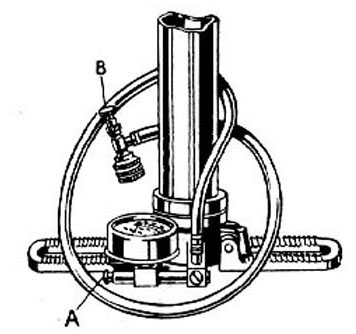

Screw the coupling on to the valve and press down the knob B to open the valve and allow air to fill the pump tube. Press the button A by foot to read the pressure gauge, but always release the button while pumping to avoid damage to the gauge. Occasionally oil the pump with neatsfoot or olive oil through holes in the cap on the barrel.

For longest life, the tyre pressures should be adjusted accurately to suit the load on each axle as shown in the table.

Normal conditions are:-

Model M (51/4in for 21in rim) 38lb. front, 50lb. rear

Model Q (31in x 5.25in) 30lb. " 34lb. "